controlled atmosphere cold storage

controlled atmosphere cold storage Specification

- Usage

- Industrial

- Function

- Controlled Atmosphere Cold Storage

- Refrigerant

- R404a

- Application

- Fruit and Vegetable Storage

- Product Type

- Walk In Chiller

- Air Volume

- 1800 m/h

- Thickness(mm)

- 100 mm

- Door Type

- Swing Door

- Power

- 2.5 kW

- Voltage

- 220 V / 380 V

- Cooling System

- Direct Expansion

- Temperature

- -25C to +15C

- Defrost Type

- Automatic Electric Defrost

controlled atmosphere cold storage Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Month

- Delivery Time

- 1 Months

- Main Domestic Market

- Gujarat

- Certifications

- ISO:9001-2008

About controlled atmosphere cold storage

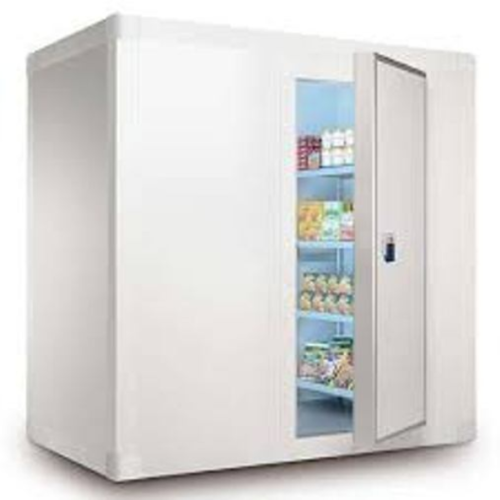

Walk In Chiller

Since our establishment in the year 1960, we are engaged in manufacturing and exporting an excellent array of Walk In Chillers. The offered chiller is in extremely demand in the market due to its accurate functioning. While manufacturing this chiller our skilled personnel team uses high-quality materials that are obtained from genuine vendors in the market. This chiller is widely used to cool or freeze vegetables, beverages, food, meat, fruit, pharmaceutical material, and chemicals stored inside. We offer Walk-In Chiller to the patrons as per their required specifications at reasonable prices.

Key Features:

- Robust structure

- Longer functional life

- Requires less maintenance

- Further Details:

Walk-in Chillers:

Walk-in chillers to suit your requirements ranging from hotel & food chains to hospitals & research centers. We offer an extensive range of cold room solutions, in a choice of temperatures to suit a variety of requirements and budgets.

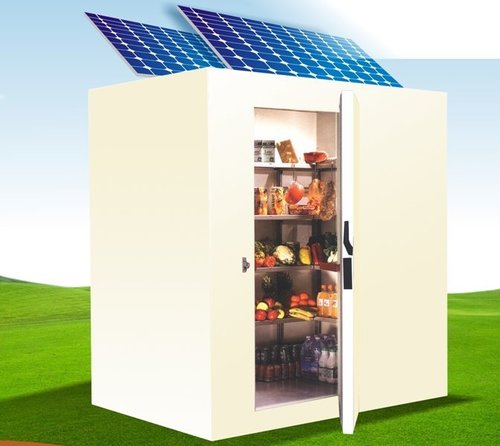

Optimal Preservation with Advanced Control

This cold storage system uses advanced microprocessor controls and digital thermostats to optimize storage conditions. Adjustable humidity and precise temperature settings ensure fruits and vegetables remain fresh. CO2 and O2 sensors help regulate atmospheric composition, improving shelf life and reducing spoilage.

Durable Construction and Efficient Cooling

Constructed with Pre-painted Galvanized Iron panels and polyurethane foam insulation, the unit offers excellent durability and thermal efficiency. Emerson/Danfoss compressors and direct expansion cooling maximize energy effectiveness, while stainless steel shelves provide hygienic and robust storage.

User-Friendly Features and Safety

The storage units swing door with anti-frost heater, automatic electric defrost, and microprocessor-based control system enable easy operation. Safety features, such as humidity control and digital sensors, help maintain ideal conditions and protect stored goods.

FAQs of controlled atmosphere cold storage:

Q: How does the controlled atmosphere cold storage maintain optimal conditions for fruit and vegetable preservation?

A: The storage system combines adjustable humidity (from 65% to 95%) and a wide temperature range (-25C to +15C), managed by a microprocessor and digital thermostat. CO2 and O2 sensors monitor and regulate atmospheric gases, ensuring produce remains fresh and safe for longer periods.Q: What materials are used in the construction of this cold storage unit?

A: Pre-painted Galvanized Iron (PPGI) forms the exterior panels, while polyurethane foam is used for insulation. The shelving is made from stainless steel, offering durability and resistance to corrosion, ideal for industrial settings.Q: When is this cold storage typically used during the supply chain process?

A: This unit is deployed immediately after harvesting to extend the shelf life of fruits and vegetables during storage, transit, and distribution. It is crucial for exporters, manufacturers, and suppliers who need to maintain product quality before market delivery.Q: Where can these controlled atmosphere cold storage units be installed?

A: They are suitable for installation in farms, packaging centers, warehouses, distribution hubs, or export facilities across India. Their industrial-grade materials and design enable use in various climates and operational environments.Q: What are the benefits of using automatic electric defrost and anti-frost door heaters?

A: Automatic electric defrost prevents ice build-up on cooling coils, enhancing performance and minimizing maintenance. Door heaters help avoid frost formation around the swing door, ensuring easy access and continuous cold chain integrity.Q: How does the microprocessor-based control system improve cold storage operations?

A: The microprocessor-based control system provides precise management of temperature, humidity, and gas levels by continuously monitoring real-time conditions. This automation increases efficiency, reduces human error, and helps maintain a stable storage environment for sensitive produce.

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Month

- Delivery Time

- 1 Months

- Main Domestic Market

- Gujarat

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

MECH AIR INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |