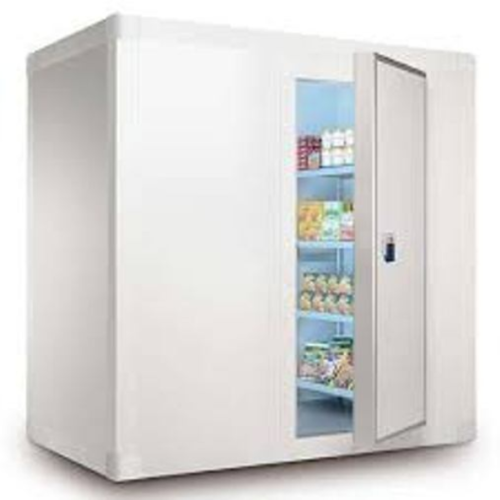

Pre Cooling Machine

Pre Cooling Machine Specification

- Voltage

- 220V / 380V

- Door Type

- Insulated Swing Door

- Air Volume

- 4500 m/h

- Application

- Vegetable & Fruit Pre-Cooling

- Thickness(mm)

- 100 mm

- Defrost Type

- Automatic Hot Gas

- Usage

- Industrial / Commercial

- Function

- Rapid Cooling of Fresh Produce

- Power

- 5 HP

- Product Type

- Pre Cooling Machine

- Cooling System

- Forced Air / Evaporator Fan

- Temperature

- -5C to +10C Adjustable

- Refrigerant

- R404A / Eco-Friendly Option

- Protection

- Overload and Phase Protection

- Cooling Time

- 30 to 240 minutes (depending on load)

- Material

- High-Quality Stainless Steel Interior/Exterior

- Insulation Type

- PUF Panel

- Noise Level

- < 65 dB

- Dimension

- Customizable Standard: 10ft x 10ft x 8ft

- Mobility

- Optional Wheels for Easy Movement

- Installation

- On-site Installation Provided

- Humidity Control

- 60% to 95% Adjustable

- Floor Type

- Anti-Skid Stainless Steel

- Controller Type

- Digital Temperature Controller

- Lighting

- LED Interior Lighting

- Capacity

- 2 to 6 Ton Per Batch

- Compressor Brand

- Imported/Indian Brands Available

Pre Cooling Machine Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1 Number Per Month

- Delivery Time

- 1 Months

- Main Domestic Market

- All India

About Pre Cooling Machine

Basis of design for Precooling Room

| 20ft.(L) x 10ft.(W) x 11ft.(H) Ext. dim. |

| 01 |

| Prefabricated 80mm PUF Panels

|

| Fruits & Vegetables 5MT/batch |

Pre Cooling (Product incoming temp.) | +35C |

product Temp./ Room temp ) | +2-7C (Settable as per your requirement) |

| 90 % RH |

| 4-5 hours |

| Forced Air Precooling |

insulation purpose | 52 Deg.C maximum |

refrigeration system | +42C |

| 0.9 x 2.0mtr.(H) with manual swing |

| Mech Air make refrigeration unit |

| R-22 |

| Emersons make |

| Hermetic |

| Axial flow fans |

| 4 Watt/m2 with vapour proof light fixture |

| As per overleaf |

| All of reputed make of Telemechanic/Seimens/L&T |

| All coils & pipes are of copper make duly insulated |

| Sensitivity 1 Deg.C |

| 415V/3 phase/50 HZ |

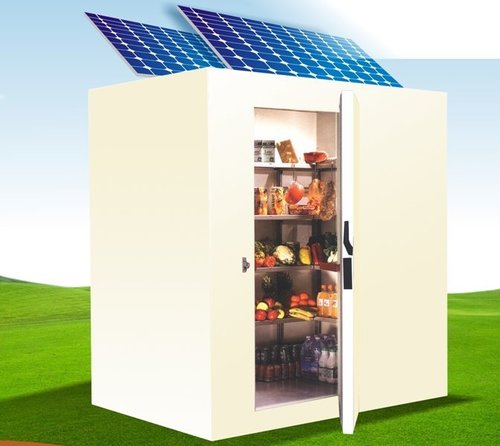

Advanced Cooling Technology

Utilizing a forced air cooling system with an automatic hot gas defrost, the Pre Cooling Machine delivers rapid and uniform temperature reduction. Its reliable compressoravailable from leading imported or Indian brandsensures consistent performance for optimizing the freshness and shelf life of produce.

Customizable and User-Friendly Design

Tailor the Pre Cooling Machine to your operational needs with customizable dimensions and optional mobility via wheels. The insulated swing door, anti-skid flooring, and intuitive digital controller provide safety, convenience, and precision for any industrial or commercial environment.

Safe, Eco-Friendly, and Robust Performance

Designed for long-term durability, the pre-cooler combines PUF insulation and robust stainless steel construction with overcurrent and phase protection features. The use of eco-friendly refrigerants and low-noise operation (<65 dB) ensures energy efficiency and compliance with environmental standards.

FAQs of Pre Cooling Machine:

Q: How does the Pre Cooling Machine enhance the freshness of fruits and vegetables?

A: The machine rapidly reduces the temperature of freshly harvested produce, slowing down respiration and delaying spoilage. This process preserves firmness, color, and nutrients, ensuring fruits and vegetables remain fresh for longer periods.Q: What process does the Pre Cooling Machine use to achieve rapid cooling?

A: It employs a forced air or evaporator fan cooling system with an automatic hot gas defrost, ensuring uniform and efficient temperature reduction throughout the chamber. The digital temperature controller offers precise adjustment from -5C to +10C.Q: When should I use the Pre Cooling Machine during my produce logistics?

A: It is best used immediately after harvest or post-receipt of produce at your facility. Early pre-cooling helps maintain product quality during storage and transport by removing field heat quickly.Q: Where can the Pre Cooling Machine be installed, and is installation assistance provided?

A: It is suitable for installation at farms, packaging centers, warehouses, and industrial facilities. On-site installation is provided by the manufacturer or supplier to ensure proper setup and operation.Q: How is the humidity and temperature controlled inside the machine?

A: The machine features an adjustable digital controller for both temperature (-5C to +10C) and humidity (60% to 95%), allowing you to tailor conditions for different types of produce and storage needs.Q: What are the main benefits of using the Pre Cooling Machine in commercial operations?

A: Key benefits include significant improvement in product shelf life, reduction in post-harvest losses, energy-efficient operation, and enhanced produce safety due to its robust, hygienic, and easy-to-clean stainless steel design.

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1 Number Per Month

- Delivery Time

- 1 Months

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

MECH AIR INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |